5 Benefits of Using the 5S System for Managing Tools and Equipment

By Grainger Editorial Staff 9/14/23

The 5S system helps create a clean, well-organized and standardized work environment to improve safety and productivity. While the system is widely used in manufacturing, production and assembly line industries, it can also be applied to other areas, like tool and equipment management. Learn how it works and see if your business could benefit from implementing the 5S system.

What is the 5S System?

The 5S system is based on Japanese lean manufacturing principles designed to help improve the efficiency and productivity of work environments through better organization and reduced waste. The five steps in the 5S system are Sort, Set in Order, Shine, Standardize and Sustain. Each step is specifically designed to help improve a work area.

“5S is a methodology that results in a clean, uncluttered and safer workplace,” said Brandon Verzal, a national account manager for Stanley Black & Decker.

5 Benefits of Using the 5S System

Using the 5S system to manage tool and equipment inventory has several benefits, including:

- Improved safety: When tools and equipment are easier to find and use, there is less clutter to trip over or fall on. From an ergonomic perspective, keeping tools closer can help reduce worker fatigue. Cleaner workspaces also help prevent slip and fall incidents and lower the risk of other safety hazards.

- Increased efficiency: Employees save time by quickly finding the tools and equipment they need leading to increased productivity and less downtime. “Having the right tools in the right place at the right time helps cut out seconds per tool grab,” said Verzal.

- Better quality: A messy and disorganized workplace can lead to mistakes. With a clean and tidy workspace, there is less chance for tools and equipment to become lost or damaged.

- Lower costs: Improved organization can reduce the need for new tools and equipment, which results in less waste and rework.

- Boost morale: Employees’ mental and physical health benefit from a clean, organized workspace and a more pleasant work environment.

How to Implement the 5S System

Sort

To start using the 5S system to organize your tool inventory, gather all your hand tools, power tools, accessories and storage containers. Sort all tools and equipment into three categories: necessary, unnecessary and for repair. Eliminate all unnecessary items from the workspace, keeping only essential tools and equipment.

Next stockpile unnecessary tools and remove them from the toolbox or work area. This part of sorting is a critical step. "Don’t discard any tools. Some of the unnecessary tools may be needed in a different workspace, and we can save money by collecting those,” said Verzal. Some organizations use a red/green inspection tag process, with green tags indicating the tools they plan to keep and red tags marking the tools that need to be removed for maintenance. “The red tag process can also help identify any broken tools that need to be warrantied, discarded or repaired, ensuring those tools are set aside to go through the proper process,” said Verzal.

Set in Order

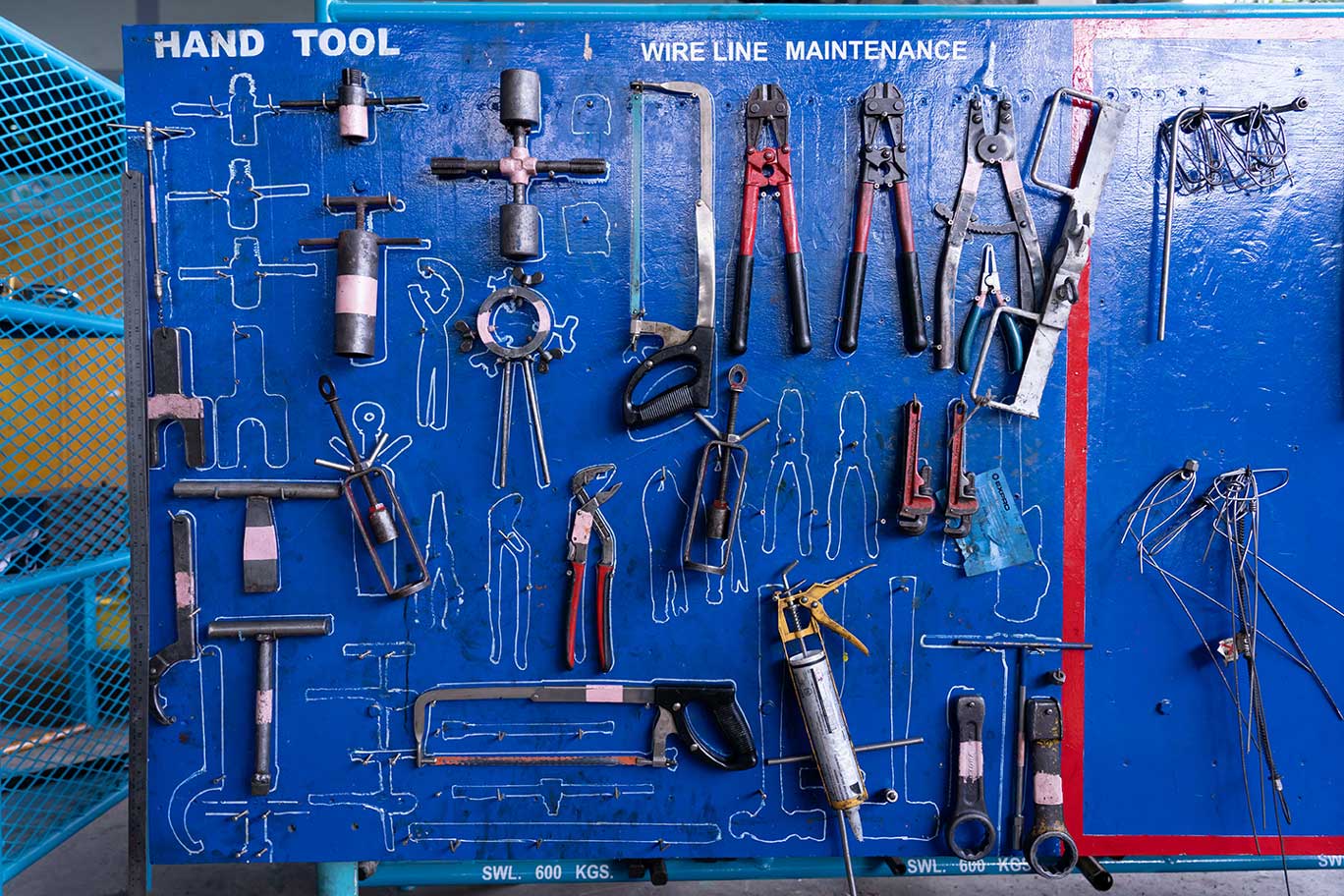

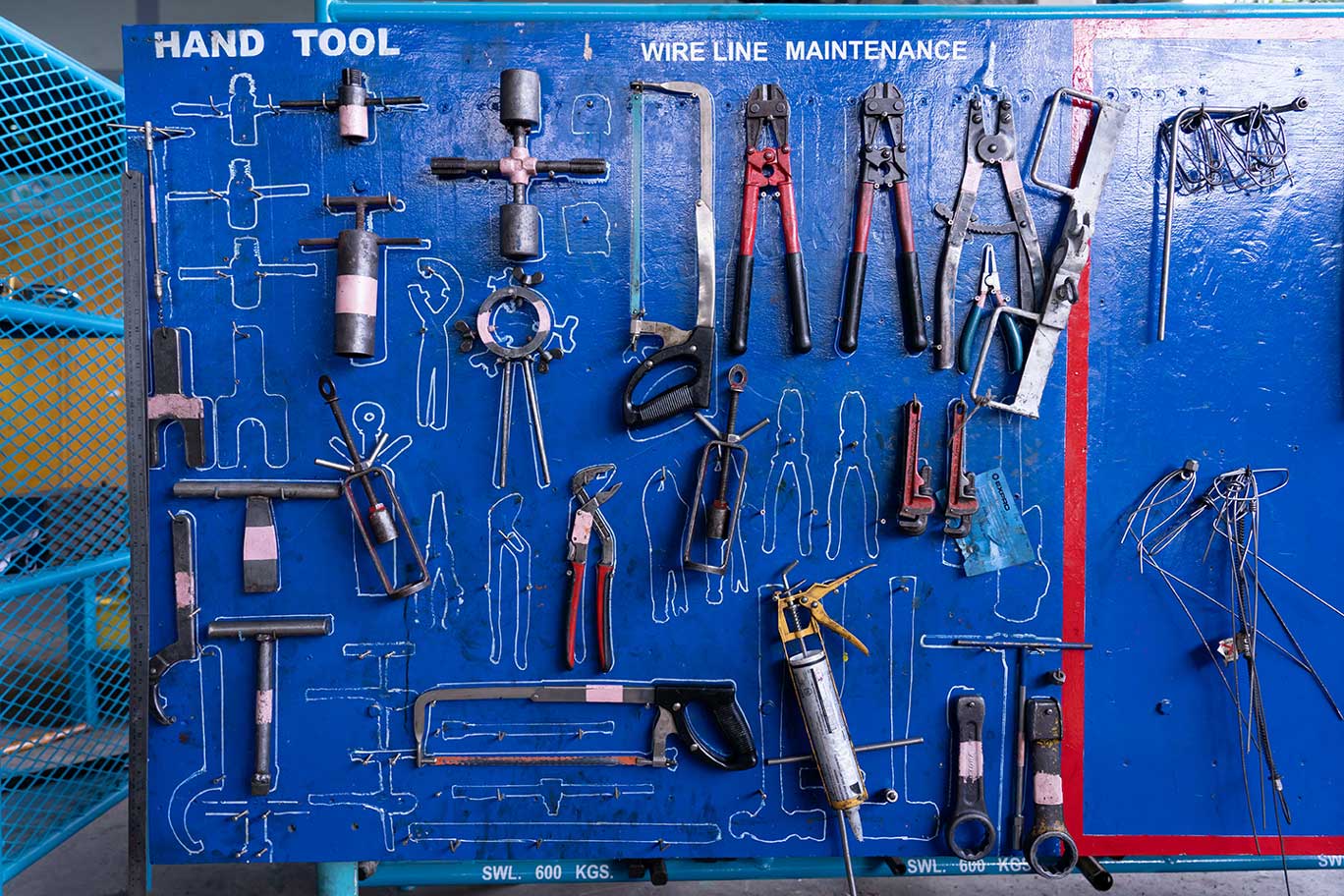

Next, organize all necessary tools and equipment in an easy-to-find logical manner. This could mean grouping or moving frequently used tools closer to the worker. You can use bins, shelves, tool lockers, cabinets and other portable or modular storage containers to help keep tools organized. Labels, shadow boards and color coding can help workers identify and locate tools quickly.

“A good rule of thumb is if the tools are used together, they should be stored and organized together, creating less reaching and user fatigue,” Verzal said.

Shine

After sorting, it’s important to clean and inspect all tools and equipment. Tools and equipment should be inspected regularly and replaced to ensure they are in good working condition. Rotating tools regularly helps ensure they are used evenly. Maintaining a tidy workspace keeps tools readily available and helps improve productivity. Routine cleaning and maintenance help reduce the risk of accidents and can extend the lifespan of tools and equipment.

Standardize

After cleaning, creating a standard process for keeping tools and equipment neat and organized is essential. These standards should be followed by everyone who works in the area to maintain consistency and efficiency. This step involves creating a tool record and setting up a system for tracking the purpose and location of all tools in your inventory.

Sustain

Make the 5S system a continuous improvement process. This step involves maintaining the improvements made during the previous steps by training employees to ensure they follow the correct procedures. Conduct regular inspections to ensure that the workspace remains organized. Employee engagement and ongoing training are essential to maintaining the system’s effectiveness, organization and cleanliness. A reward system can be a helpful way to encourage workers to sustain the 5S process.

Customize Your Approach

Every organization has unique challenges and opportunities regarding storage and organization. There is no “cookie cutter” approach to implementing a 5S system. However, for organizations looking to employ a 5S system around tooling, Verzal recommended working with a specialist to explore options like foam kitting or shadow boards, which can be customized.

Important Considerations

Despite the many benefits of a 5S system, change can be difficult. Verzal said one of the biggest challenges with 5S and lean production principles, in general, is the fifth step — the ability to sustain the work. “It has to be seen as a new process that continually has to be executed, inspected, trained, cross-trained and maintained,” he said.

Successful implementation involves creating a culture of team member accountability where everyone understands the benefits to their job and the entire facility or organization when they maintain the 5S process.

The following are some tips to consider when implementing a 5S system:

- Equipment consolidation: Many companies employing a 5S system find immediate cost savings. “Most customers can start a 5S process with the tools they currently have on hand,” Verzal said. "Most of the time, they find they have an excess of what they need and can reduce waste.”

- Product warranties: “From a warranty standpoint, keeping brands underneath one warranty makes it easier for technicians to warranty their tools leading to additional cost savings,” said Verzal. If tools aren’t standardized from a brand or distribution standpoint, technicians could throw away tools or ask for a replacement, and this unstandardized approach often results in a lot of duplicate spending.

- Research new technology: When evaluating your tool budget, it’s important to research new technology to see if there is a safer tool for a specific application. From enhanced ergonomics to vibration control, many new power tools and cordless options can help reduce worker fatigue and help to mitigate other safety hazards.

- Focus on training and communication: Provide comprehensive training to employees regarding the 5S principles, their benefits, and how to implement them effectively. Regular communication channels should be established to address questions and share progress.

- Get everyone involved: The 5S system is most effective when everyone in the workplace is involved. Ensure that employees know the system’s benefits and are allowed to participate in the implementation process.

- Start small: Don’t try to implement the 5S system in your entire workplace all at once. Start with a small area, such as a workbench or a tool cabinet. This will help you get a feel for the process and identify any challenges you may need to address.

- Be patient: The 5S system is a long-term process. “It’s taken a long time in many cases to get to the point where our workspace is cluttered and unorganized, so it’s going to take a little bit of time to employ the 5S process,” said Verzal. Don’t expect to see results overnight.

Sustainability

Understanding Nitrile and Biodegradability

Purchasing managers responsible for meeting their organization's sustainability goals should dig a little deeper when they come across product descriptions with environmental claims.

![]() OUR LATEST KNOWHOW

OUR LATEST KNOWHOW

Building Maintenance

What To Do When Water Meets Your HVAC System

This article highlights the key places throughout your HVAC system you should check for signs of water damage, leaks and other water-related issues.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.