How It's Done:

TRAC A ROD

How It's Done: Making the Trac-A-Rod

By Grainger Editorial Staff 4/17/24

Founded in 1959, Du-Bro Products and Pine Ridge© Archery is a family business headquartered in Wauconda, Illinois.

“The types of products we make here at Du-Bro Products and Pine Ridge Archery are specialty products, whether it be hardware, fasteners, or accessories for multiple industries, but more specifically for archery and fishing hobby and sport said Brian Bychowski, president and owner of the company. "We make a lot of injection-molded products, metal products, and all kinds of different gadgets and gizmos that help people enjoy their hobbies.”

Back in the 1980s, fishermen didn’t have a reliable way to store their fishing rods. This was a big problem because rods are fragile and many are custom-made, which can get quite expensive. For storage, people would often just stack the rods together, standing them up in a corner in the garage or a workshop. Without fail, rods stored like this would topple over onto one other and break.

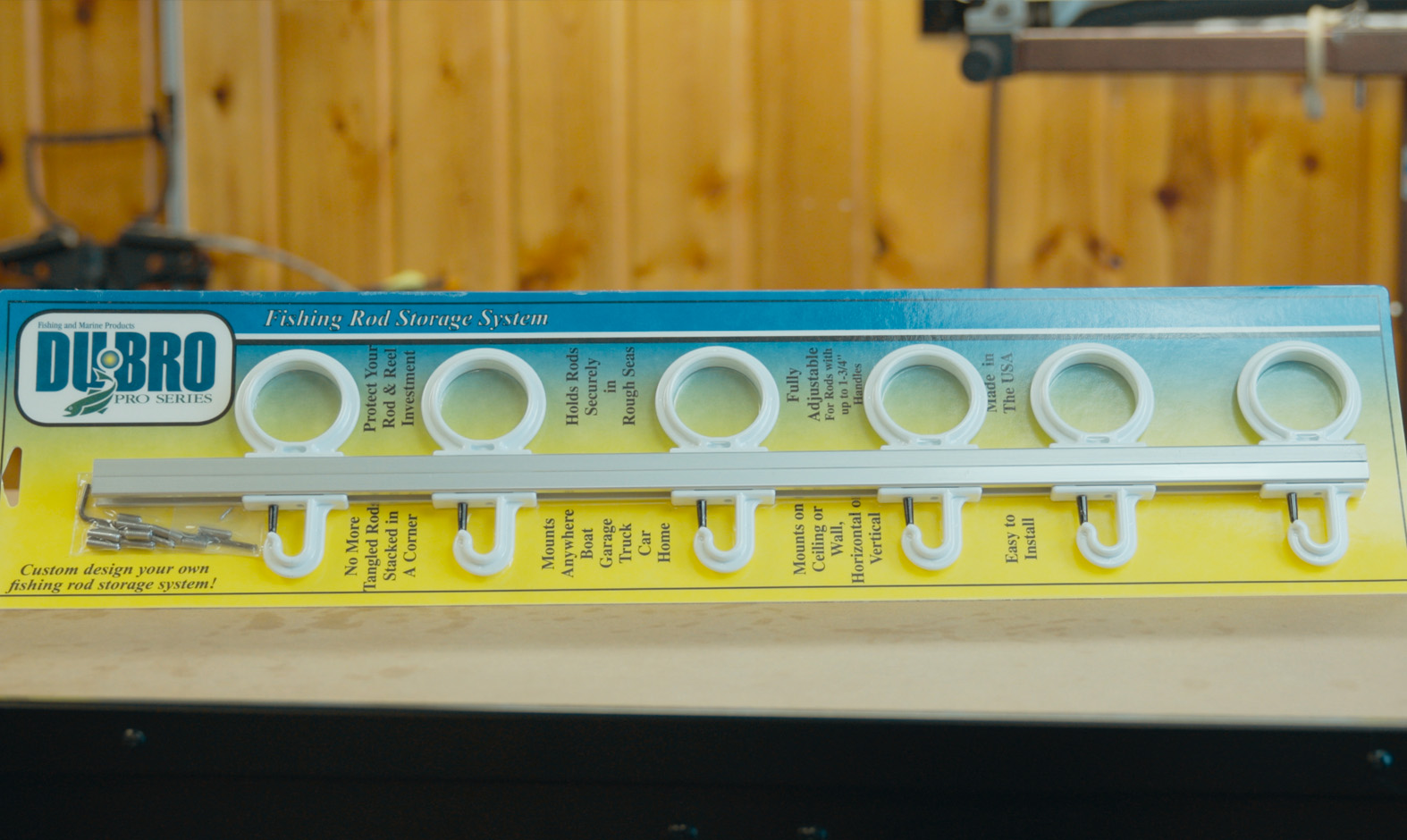

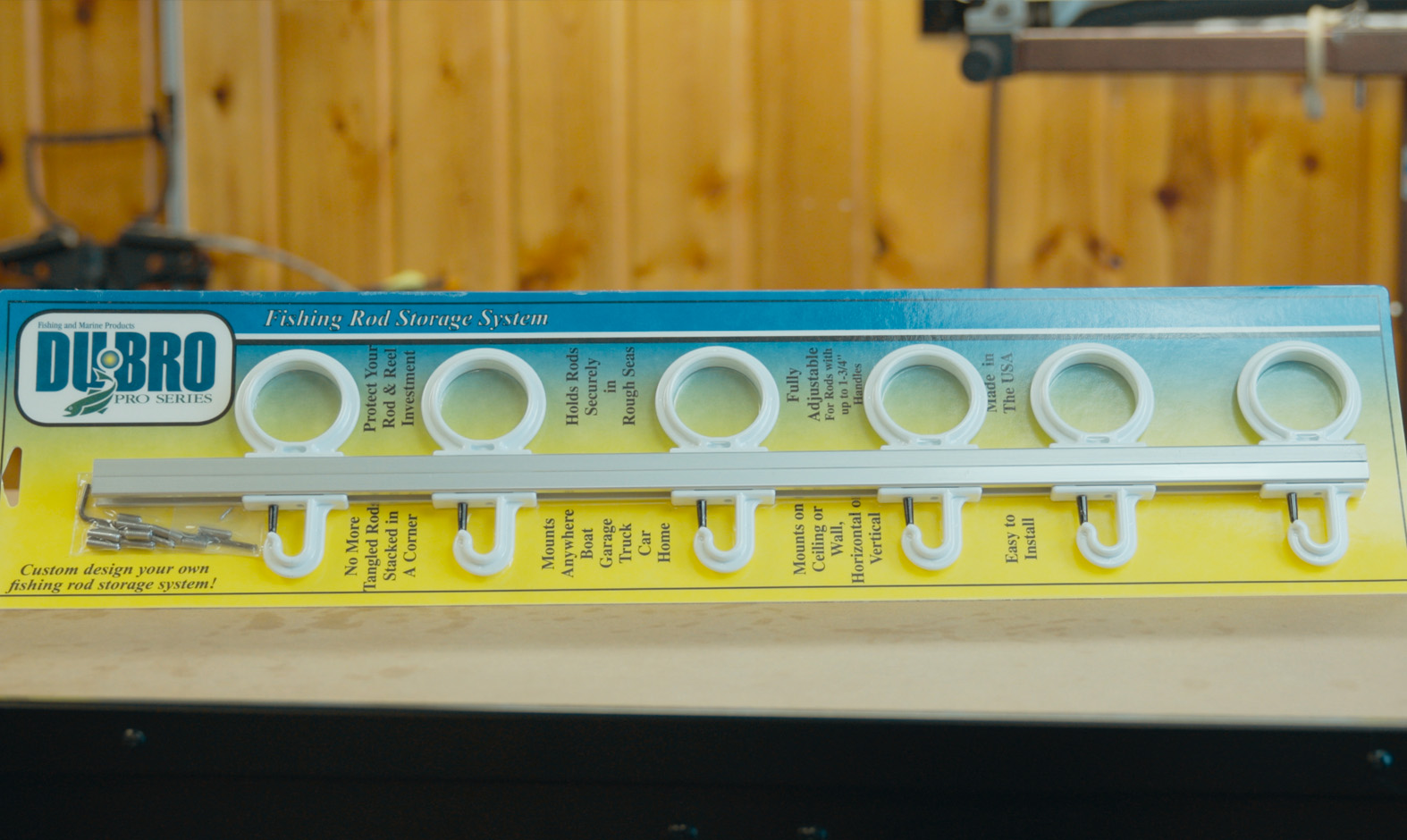

Not surprisingly, it took a fisherman to help solve the problem. Dewey Broberg was a fisherman, dividing his time between freshwater fishing on the Great Lakes and salt-water fishing off the coasts of Florida. He also is the founder of Du-Bro Products, a manufacturer of accessories for remote-control airplanes, cars and boats. Du-Bro developed a product called the Trac-A-Rod, which not only helped solve the problem of storing rods, but its unique design secures rods on boats, in RVs, or anywhere fishing rods were in use, in transit or in storage.

Today, Du-Bro Products in Wauconda, Illinois, manufactures a wide variety of gadgets for outdoor sports. Here's a quick look at the steps involved to produce the Trac-A-Rod rack system.

Concept and Design

The concept of the Trac-A-Rod was first drawn using computer-aided design. And because back in the late 1980s 3D printing didn’t exist, molds based on the design were created out of wood. With some trial and error, the concept and design for the Trac-A-Rod was born.

Injection Molding

The next step in the manufacturing process is injection molding of the hooks and rings. First the mold is dropped into the machine and is injected with virgin plastic for strength. What emerges is a hook and ring assembly that has been tapped, or threaded, so it can accept the set screw when it’s poured into the track piece.

Cutting the Tracks

The next step is taking the extruded track and cutting it to the appropriate lengths for assembly.

Assembly

The final product is assembled by hand. First the workers count out the appropriate number of J-hooks for the track length. Next, they assemble the J-hooks by pressing a flexible rubber piece into the back of each hook. The hooks are then slid into the tracking system. The final assembly will accept a fishing rod as it goes in and the flexible rubber piece helps lock it in place so rod tips won’t slip out while they’re in the holder.

Packaging

Finally the different-sized Trac-A-Rods are packaged using a backing and shrink wrap machine. Once complete, the packages are ready to be shipped for distribution to dealers and customers all over the world.

Find out how Du-Bro Products makes their Kwik Stand Bow Stand for archery enthusiasts.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.